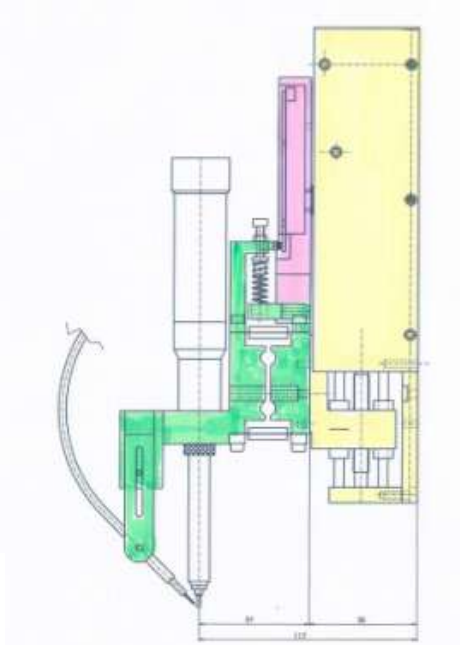

Electronically controlled / regulated Z-axis - modular system

For this specific purpose, the PosCon 1900, a self-contained, motorized Z-axis, has been developed to accommodate the ultrasonic robot soldering heads # 9200-127 and # 9500-127. With constant soldering tip force, the system can automatically compensate, substrate height differences of up to +/- 15mm.

1. Motorized Z-axis with a path of +/- 15mm. The electronic motor controller with height control is integrated in the housing

3. Electronic Height measurement with LED bargraph display. Leaf spring center position corresponds to the center of the electronic measuring device (green LED). The electronic display of the measuring system comprises 21 LEDs and corresponds to a mechanical way of the spring device of a total of 0.6 mm. Each 0.3mm upwards corresponds to 10 yellow LED and 0.3mm down also 10 yellow LED. Thus, we achieve a mechanical resolution of only 0.03mm (30祄) per LED increment, which allows a precise and very fine control of the system

In controlled operation, the motorized part of the axle travels downwards or upwards as required, so that the height measuring system always remains in the middle = green LED. This guarantees a constant force on the soldering tip.

2.1900-412 Mechanical leaf spring loaded Soldering iron holder (support) For holding the Robot soldering heads 9200-127 / 9500-127.( Illustration with optional fastener for solder wire feeder hose )

3. 1900-422 Electronic Height Measurement Device with sensor and display.

Read these operating instructions carefully first,before you make or change settings on this system. It is important that the following order of commissioning be followed exactly.